一, የኢንዱስትሪ ሮቦቶች የዘመናዊው የኢንዱስትሪ ምርት መስመር አስፈላጊ አካል ሆነዋል.

የኢንዱስትሪው የ 4.0 ዘመን መምጣት ጋር, የኢንዱስትሪ ሮቦቶች የዘመናዊው የኢንዱስትሪ ምርት መስመር አስፈላጊ አካል ሆነዋል. የኢንዱስትሪ ሮቦቶች ዋና አንቀሳቃሽ መሣሪያ እንደመሆኑ የሞተር ቴክኖሎጂ ልማት የኢንዱስትሪ ሮቦቶችን አፈፃፀም እና ቅልጥፍናን በቀጥታ ይነካል። ስቴፐር ሞተርስ፣ እንደ ሞተር አይነት፣ ቦታን እና ፍጥነትን በትክክል መቆጣጠር የሚችል፣ በኢንዱስትሪ ሮቦቶች ውስጥ ወሳኝ ሚና ይጫወታሉ። በዚህ ጽሑፍ ውስጥ የኢንደስትሪ ሮቦት ቴክኖሎጂ እድገትን በተመለከተ ማጣቀሻ ለማቅረብ ከስቴፐር ሞተርስ ፍቺ እና ባህሪያት እንጀምራለን ፣ በኢንዱስትሪ ሮቦቶች ውስጥ ስለ አተገባበሩ በዝርዝር እንወያይ እና ከሚመለከታቸው ጉዳዮች ጋር እንመረምራለን ።

የስቴፐር ሞተር ፍቺ እና ባህሪያት

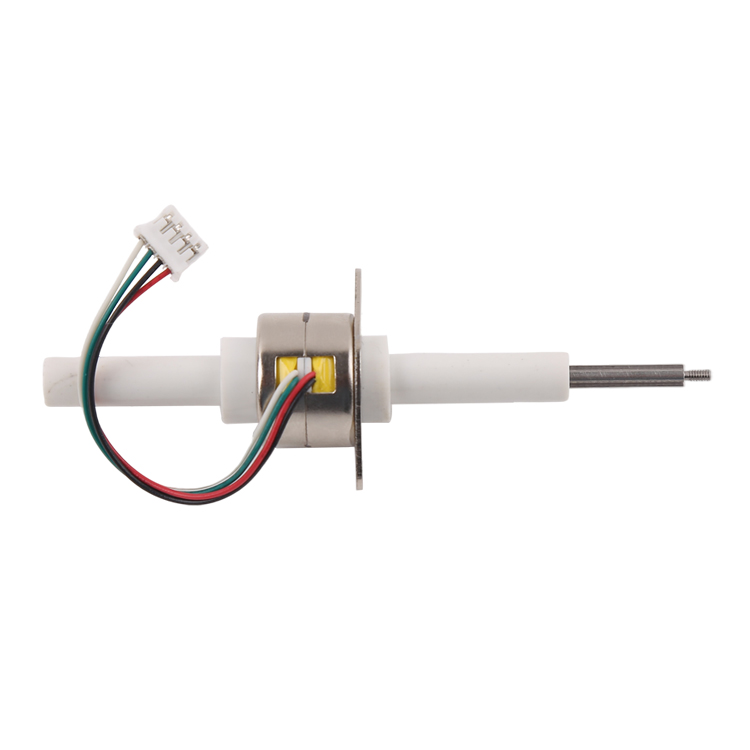

ስቴፐር ሞተር የኤሌክትሪክ ምት ምልክትን ወደ አንግል ማፈናቀል ወይም የመስመር መፈናቀል የሚቀይር ሞተር አይነት ነው። በጣም መሠረታዊ በሆነው የኤሌክትሮማግኔቲክ መርህ ላይ የተመሰረተ ነው, እና የ pulse ምልክቶችን ድግግሞሽ እና ብዛት በመቆጣጠር የሞተር መዞር አንግል እና የፍጥነት ትክክለኛ ቁጥጥርን ይገነዘባል. ስቴፐር ሞተር የሚከተሉትን ባህሪዎች አሉት ።

ትክክለኛ ቁጥጥር;የእርከን ሞተር ትክክለኛ የቦታ መቆጣጠሪያን በትክክለኛ የልብ ምት መቆጣጠሪያ ሊገነዘበው ይችላል, እና የአቀማመጥ ትክክለኛነት 0.001 ° ሊደርስ ይችላል.

ቀላል የመቆጣጠሪያ ሁነታ;የእርከን ሞተር ቁጥጥር በአንፃራዊነት ቀላል ነው ፣ እንቅስቃሴን ለመቆጣጠር የ pulse ምልክትን ድግግሞሽ እና አቅጣጫ መቆጣጠር ብቻ ያስፈልጋል ፣ ውስብስብ የግብረመልስ ማስተካከያ ማድረግ አያስፈልግም።

ከፍተኛ አስተማማኝነት እና መረጋጋት;የስቴፐር ሞተሮች ከፍተኛ አስተማማኝነት እና መረጋጋት አላቸው, እና ያለ ቀላል ጉዳት እና ውድቀት ለረጅም ጊዜ ሊሰሩ ይችላሉ. ከሌሎች የሞተር ዓይነቶች ጋር ሲወዳደር ስቴፐር ሞተሮች ብሩሾች እና ተጓዦች እና ሌሎች የመልበስ ክፍሎች የላቸውም, ስለዚህ ህይወት ረጅም ነው, የጥገና እና የጥገና ወጪዎች ዝቅተኛ ናቸው.

ዝቅተኛ-ፍጥነት, ከፍተኛ-የማሽከርከር ባህሪያት:የስቴፐር ሞተሮች በዝቅተኛ ፍጥነት ከፍተኛ የማሽከርከር ችሎታ አላቸው, ይህም ከፍተኛ የማሽከርከር ውፅዓት በሚያስፈልጋቸው ሁኔታዎች ውስጥ እንዲጠቀሙ ያስችላቸዋል.

ዝቅተኛ የኃይል ፍጆታ;ስቴፐር ሞተሮች አብዛኛውን ጊዜ ጉልበት የሚወስዱት ለመንቀሳቀስ በሚያስፈልግበት ጊዜ ብቻ ነው፣ እና ቦታ ሲይዙ ምንም ኃይል አይጠቀሙም ፣ ስለሆነም አነስተኛ የኃይል ፍጆታ አላቸው።

በኢንዱስትሪ ሮቦቶች ውስጥ የስቴፐር ሞተሮችን መተግበር

ትክክለኛ አቀማመጥ እና የእንቅስቃሴ ቁጥጥር

የኢንደስትሪ ሮቦቶች የተለያዩ ውስብስብ ስራዎችን ለማጠናቀቅ የመጨረሻውን ተፅእኖ ያላቸውን አቀማመጥ እና አመለካከት በትክክል መቆጣጠር አለባቸው. የስቴፐር ሞተሮች በትክክለኛ የልብ ምት ቁጥጥር የኢንደስትሪ ሮቦቶች የመጨረሻ ውጤት ከፍተኛ ትክክለኛነትን እና የእንቅስቃሴ ቁጥጥርን ሊገነዘቡ ይችላሉ። ለምሳሌ፣ በሚገጣጠሙበት ወቅት ስቴፐር ሞተሮች የሮቦትን እጆች እና ጣቶች እንቅስቃሴ በትክክል በመቆጣጠር ክፍሎቹ በተመረጡበት ቦታ በትክክል መቀመጡን ማረጋገጥ ይችላሉ። ይህ ትክክለኛ ቁጥጥር የኢንደስትሪ ሮቦትን ውጤታማነት እና የምርቱን ጥራት ያሻሽላል።

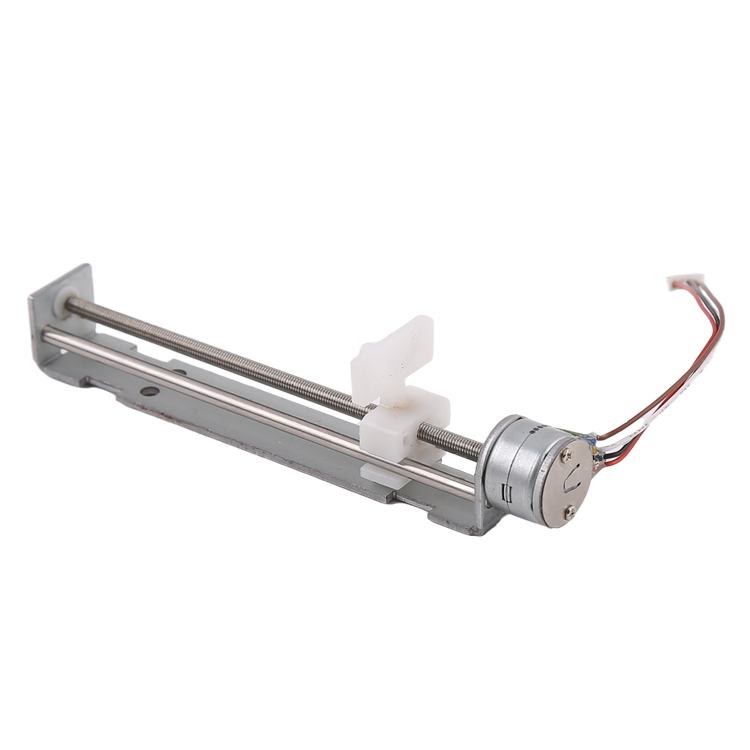

የሮቦት የጋራ መቆጣጠሪያ

ውስብስብ የእንቅስቃሴ አቅጣጫዎችን ለመድረስ የኢንዱስትሪ ሮቦቶች መገጣጠሚያዎች ብዙውን ጊዜ በበርካታ ሞተሮች ይንቀሳቀሳሉ. የስቴፐር ሞተሮች ለጋራ ድራይቭ ሞተሮች አማራጭ ናቸው, እና የእነሱ ከፍተኛ ትክክለኛነት እና ቀላል የቁጥጥር ዘዴዎች የጋራ መቆጣጠሪያን በቀላሉ እንዲገነዘቡ ያደርጉታል. የስቴፕፐር ሞተሮችን የማዞሪያ አንግል እና ፍጥነት በመቆጣጠር የኢንዱስትሪ ሮቦቶች የጋራ እንቅስቃሴ የተለያዩ ውስብስብ እንቅስቃሴዎችን እና አቀማመጦችን ለመገንዘብ በትክክል መቆጣጠር ይቻላል።

የመጨረሻ-ውጤት ቁጥጥር

End-effector ለኢንዱስትሪ ሮቦቶች እንደ ግሪፐር፣ ብየዳ ሽጉጥ፣ወዘተ የመሳሰሉ ተግባራትን ለማከናወን ቀጥተኛ መሳሪያ ነው።የስቴፐር ሞተርስ ትክክለኛ መቆንጠጫ፣መለቀቅ፣ብየዳ እና ሌሎች ስራዎችን እውን ለማድረግ የፍጻሜውን ውጤት ለመንዳት ሊያገለግል ይችላል። በእርከን ሞተሮች ከፍተኛ አስተማማኝነት እና መረጋጋት ምክንያት የረጅም ጊዜ ሥራ ላይ የመጨረሻውን ተፅእኖ መረጋጋት እና አስተማማኝነት ማረጋገጥ ይችላል.

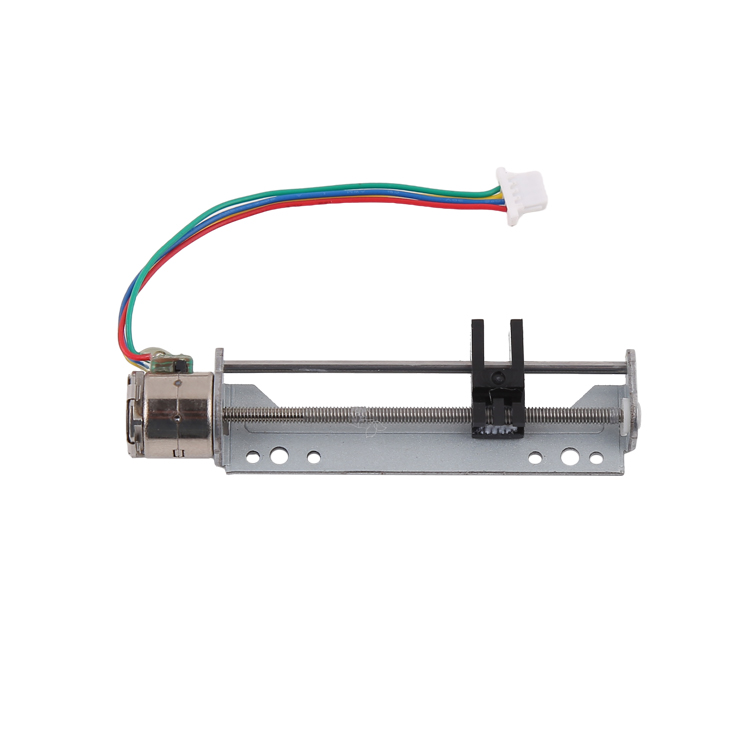

የእንቅስቃሴ መድረክ ቁጥጥር

በኢንዱስትሪ ሮቦት ስርዓት ውስጥ የእንቅስቃሴ መድረክ አጠቃላይ እንቅስቃሴን እና አቀማመጥን ለመገንዘብ የሮቦት አካል እና የመጨረሻ ውጤትን ለመሸከም ይጠቅማል። የሮቦቱን አጠቃላይ የከፍተኛ ትክክለኛነት አቀማመጥ እና እንቅስቃሴን ለመገንዘብ የእርከን ሞተሮችን የእንቅስቃሴ መድረክን እንቅስቃሴ ለመንዳት ሊያገለግል ይችላል። የእርከን ሞተሮችን አቅጣጫ እና ፍጥነት በመቆጣጠር የሮቦትን መረጋጋት እና ትክክለኛነት ማረጋገጥ ይቻላል.

ተግባራዊ የመተግበሪያ ጉዳዮች

የአውቶሞቢል አምራች የሆነውን የብየዳ ሮቦትን እንደ ምሳሌ በመውሰድ ሮቦቱ ስቴፐር ሞተሮችን እንደ የጋራ አሽከርካሪ ሞተሮች ተቀብላለች። የስቴፐር ሞተር የማዞሪያውን አንግል እና ፍጥነት በትክክል በመቆጣጠር ሮቦቱ የመገጣጠሚያውን ሽጉጥ ወደ ተጠቀሰው ቦታ በትክክል ማንቀሳቀስ እና ትክክለኛ የመገጣጠም ስራዎችን ማከናወን ይችላል። ከተለመዱት የሰርቮ ሞተሮች ጋር ሲነጻጸር, ስቴፕፐር ሞተሮች ከፍተኛ የአቀማመጥ ትክክለኛነት እና መረጋጋት ብቻ ሳይሆን ዝቅተኛ ዋጋ እና ቀላል ቁጥጥር ይሰጣሉ. ይህ የብየዳ ሮቦት ምርታማነትን በማሻሻል እና የምርት ወጪን በመቀነስ ረገድ አስደናቂ ውጤቶችን እንዲያገኝ ያደርገዋል።

四, ማጠቃለያ

የስቴፐር ሞተሮች ለትክክለኛ ቁጥጥር, ቀላል የቁጥጥር ዘዴዎች, ከፍተኛ አስተማማኝነት እና መረጋጋት በኢንዱስትሪ ሮቦቶች ውስጥ በስፋት ጥቅም ላይ ይውላሉ. የስቴፕፐር ሞተርን የማሽከርከር አንግል እና ፍጥነት በትክክል በመቆጣጠር የኢንደስትሪ ሮቦቶችን የመጨረሻ-ተፅእኖ ፣ መገጣጠሚያዎች እና የእንቅስቃሴ መድረክን በከፍተኛ ትክክለኛነት መቆጣጠር እና የኢንዱስትሪ ሮቦቶችን የስራ ቅልጥፍና እና የምርት ጥራት ማሻሻል ይችላል። በኢንዱስትሪው 4.0 ዘመን መምጣት እና የማሰብ ችሎታ ያለው የማምረቻ እድገት ቀጣይነት ያለው እድገት ፣ የስቴፕለር ሞተሮችን በኢንዱስትሪ ሮቦቶች ውስጥ መተግበሩ ሰፊ የወደፊት ተስፋ ይኖረዋል።

የልጥፍ ሰዓት፡- ኦክቶበር-31-2024